Wine & spirits

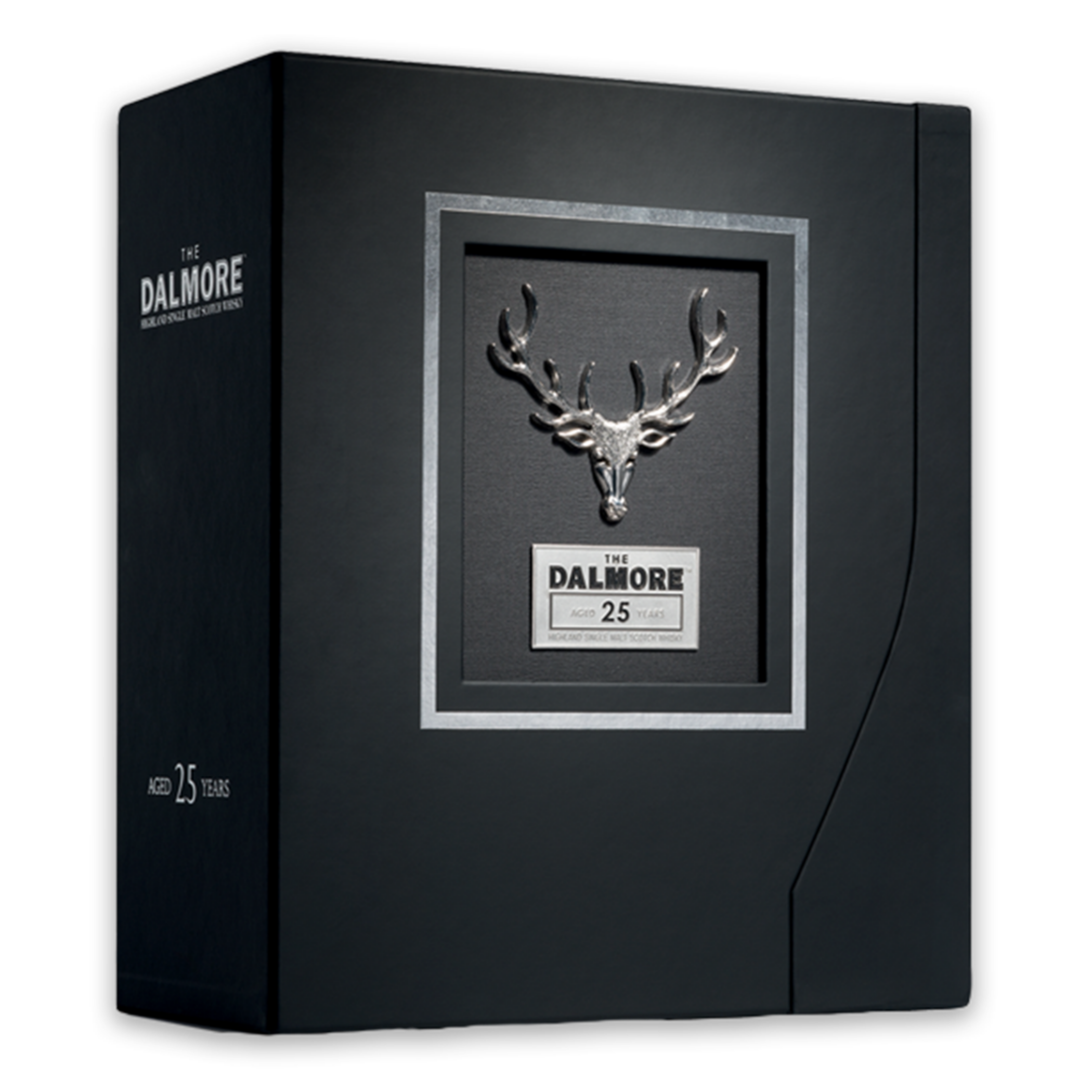

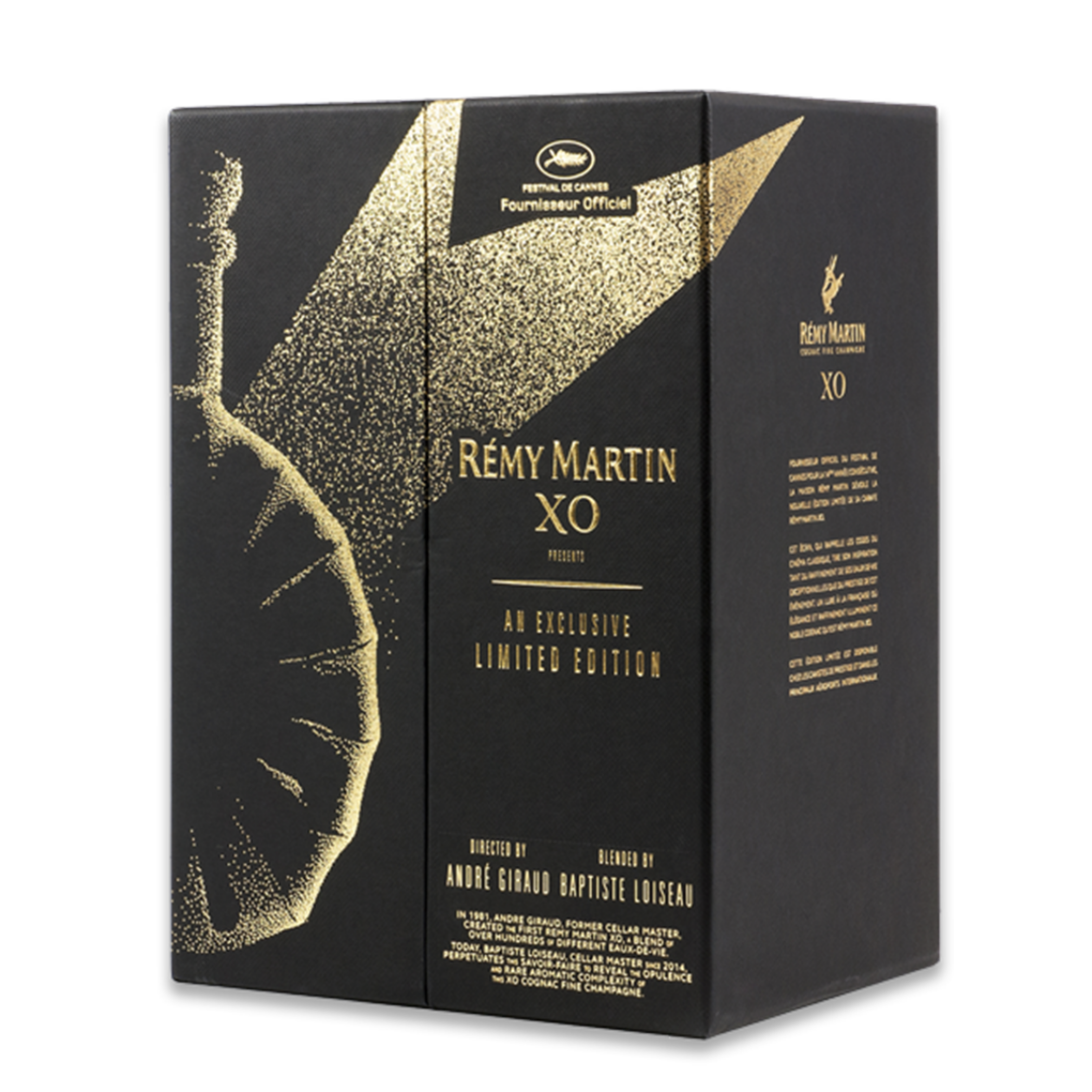

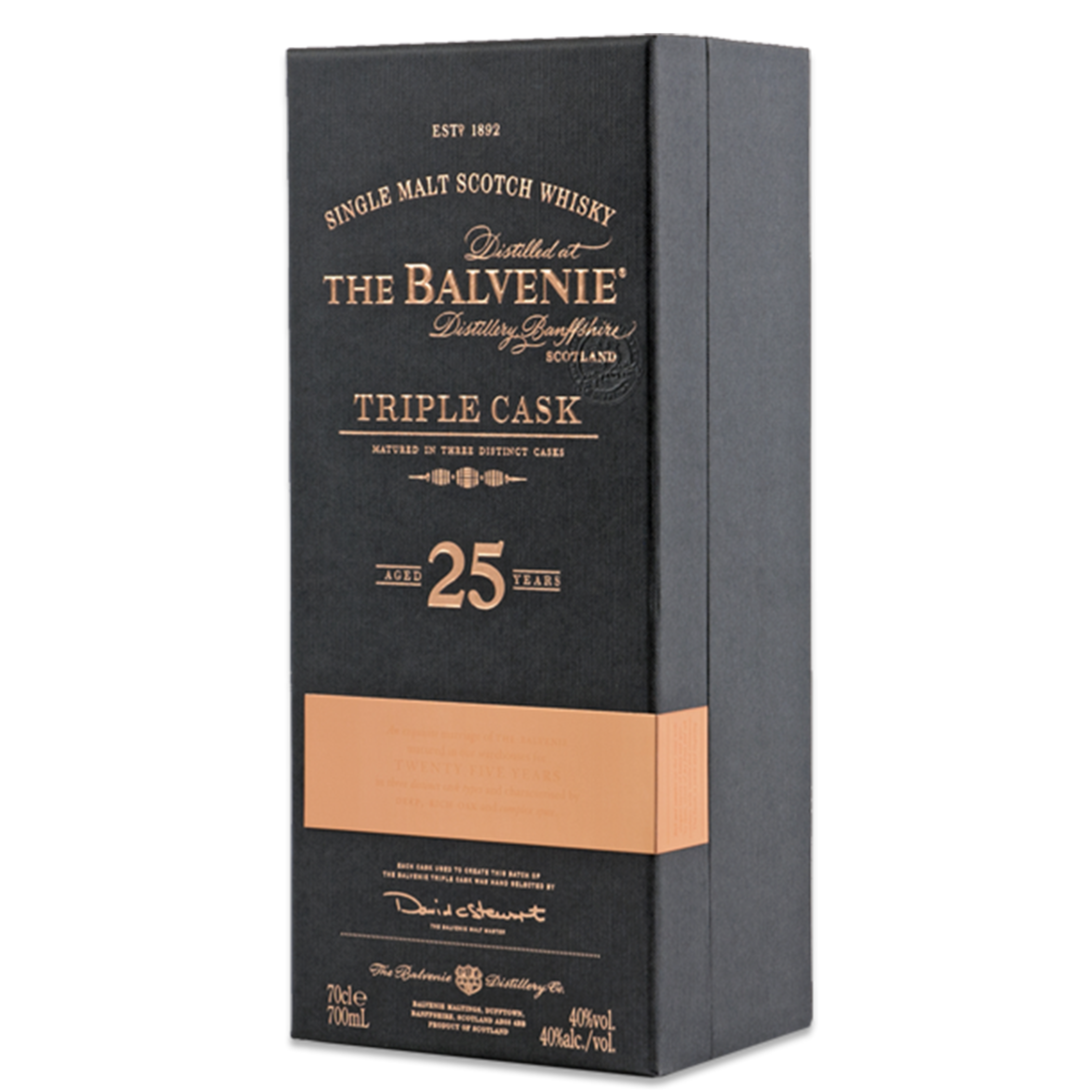

The finest flavours demandthe finest finish

First impressions last, and last and last.

A luxury wines or spirits experience begins, not on the tip of your tongue, but with your eyes. Working with brand owners, designers and manufacturers, we develop solutions to tempt all the senses.

Let’s raise a glass to that.

Our wines and spirits boards

We may lead in lots of markets, but we never forget our roots.

- Lays flat, stays flat

- Recycled fibres

- Solid coloured

- High rigidity

- Optimum runability

We believe our success is down to the reputation of our solid board. For generations we’ve refused to compromise on the highest standards, both ethically and on quality - giving our customers a flawless service all round.

- Lays flat, stays flat

- Recycled fibres

- Solid coloured

- High rigidity

- Optimum runability

We believe our success is down to the reputation of our solid board. For generations we’ve refused to compromise on the highest standards, both ethically and on quality - giving our customers a flawless service all round.

High-end luxury, low-eco impact

Using 100% recycled raw materials, eco-friendly production processes and a low-zero waste programme, we put the responsibility into luxury.

The highest quality boards. The deepest colours. The finest textures –and yet kind to the environment?

It has to be Eska.

Unique propertiesunique possibilities

At Eska, you dream, we do. Take our unique products, featuring one or two coloured sides, and displaying the inner coloured board at the cutting edge.

Seamless, superior and always in the spirit of luxury. Cheers to that!